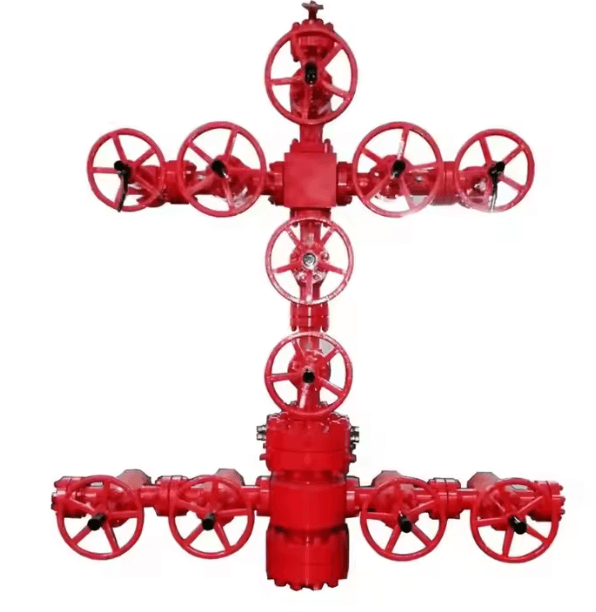

In the oil and gas industry, the term “Christmas tree” refers to an assembly of valves, spools, and fittings mounted on a wellhead to regulate the flow of oil, gas, or water from a well.

Its name derives from its resemblance to a decorated Christmas tree, with its series of valves and gauges symbolizing the “ornaments.”

Despite its festive-sounding name, the Christmas tree is a critical piece of equipment that ensures safety, operational efficiency, and production control in oil and gas operations, both onshore and offshore.

What is the Christmas Tree?

A Christmas tree is installed directly above the wellhead, which is the primary sealing mechanism that contains well pressure and acts as a safety barrier.

While the wellhead and the Christmas tree are often discussed together, they serve different but complementary purposes.

The wellhead provides structural and pressure containment for the well, while the Christmas tree manages the flow of hydrocarbons and allows operators to intervene, monitor, and control production activities.

The assembly consists of various valves, fittings, and spools that are specifically engineered to withstand the high pressures, temperatures, and corrosive environments often encountered in oil and gas production.

Its design and components vary depending on the type of well—whether it is an oil, gas, water injection, or gas lift well—and the environmental conditions under which it operates.

Key Components of the Christmas Tree

A typical Christmas tree comprises several critical components, each serving a unique function:

- Master Valve: Positioned at the base, this valve controls the main flow of fluids from the well to production facilities. It can be closed to shut off the well entirely.

- Wing Valves: Located on the sides, wing valves direct the flow of production fluids to pipelines or separators. One wing valve is typically used for production, while the other may be reserved for maintenance or alternate flow routes.

- Swab Valve: Found at the top of the Christmas tree, the swab valve allows access for interventions, such as inserting tools or cleaning equipment.

- Choke Valve: This component regulates flow rates by controlling the pressure and volume of fluids exiting the well.

- Pressure Gauges and Sensors: Installed at various points, these provide real-time data on pressure, temperature, and flow rate, allowing operators to monitor the well’s performance.

Functions of the Christmas Tree

The Christmas tree is a multifunctional device that plays an indispensable role in oil and gas production.

Its primary functions include:

- Flow Control: By regulating the flow of hydrocarbons, the Christmas tree ensures that production meets operational and safety requirements. Valves can be adjusted to control the rate of extraction, balancing efficiency with reservoir management.

- Pressure Management: The tree helps maintain pressure within safe operating limits, preventing blowouts or damage to downstream equipment. The choke valve, in particular, is essential for pressure control.

- Injection Management: The Christmas tree facilitates the injection of substances like water, gas, or chemicals into the well. These injections can enhance oil recovery or maintain reservoir pressure, extending the well’s productive life.

- Isolation and Safety: Valves on the Christmas tree allow operators to isolate the well for maintenance, repair, or emergencies, ensuring a safe working environment.

- Monitoring and Diagnostics: Equipped with gauges and sensors, the Christmas tree enables operators to gather critical data on well performance. This information is used to optimize production and identify potential issues before they escalate.

Types of Christmas Trees

There are several types of Christmas trees, each tailored to specific operational needs and environmental conditions:

- Conventional Vertical Trees: These are the most common type, with a vertical flow path for fluids. They are widely used in onshore and shallow offshore wells.

- Horizontal Trees: Designed for subsea operations, horizontal trees feature a lateral flow path that reduces their overall height. This configuration is ideal for deepwater environments where space is limited.

- Subsea Trees: These specialized trees are installed on the seabed and are remotely operated from a surface platform or vessel. Subsea trees are engineered to withstand extreme pressures and temperatures, making them indispensable in deepwater and ultra-deepwater fields.

Evolution and Advancements

The Christmas tree has come a long way since its inception, evolving in design and functionality to meet the demands of modern oil and gas operations.

Advances in materials, manufacturing techniques, and automation have significantly enhanced the reliability and efficiency of Christmas trees.

Modern Christmas trees often incorporate smart technology, such as remote monitoring systems and automated valves, allowing operators to control wells from centralized control rooms.

These advancements have not only improved operational efficiency but also enhanced safety by reducing the need for manual interventions in hazardous environments.

Importance in the Oil and Gas Industry

The Christmas tree is a cornerstone of oil and gas production, playing a critical role in ensuring safe, efficient, and sustainable operations.

Without it, operators would lack the ability to control the flow of hydrocarbons effectively, jeopardizing both safety and profitability.

By enabling precise flow and pressure management, the Christmas tree helps maximize reservoir recovery while minimizing environmental impact.

Its robust construction and adaptability to various well conditions make it a versatile solution for oil and gas extraction across the globe.

Conclusion

Though its name may suggest a festive connotation, the Christmas tree is a highly sophisticated piece of equipment integral to the oil and gas industry.

By managing production, ensuring safety, and enabling advanced monitoring and control, it serves as the backbone of successful well operations.

As technology continues to advance, the Christmas tree will remain a vital component of energy production, adapting to meet the challenges of increasingly complex reservoirs and environmental considerations.

In essence, the Christmas tree is much more than a name—it is a testament to engineering innovation and the relentless pursuit of operational excellence in the energy sector.